SOLSTICE

Solstice® Products

Configurable Single-Wafer Platform for Advanced Electroplating and Surface Preparation

Our Solstice single-wafer platform is highly flexible and can be configured to perform a comprehensive range of electroplating and surface preparation solutions for both R&D and high-volume fab environments. Its modular platform simplifies operation and maintenance, supports a range of wafer sizes, and performs – on a single tool – electroplating processes as well as critical wafer processes including solvent strip, wet etch, metal liftoff (MLO) and single-wafer cleaning.

Solstice® LT

Semi-automated single-wafer process development with up to three chambers

TOP VIEW

Solstice® LT

Semi-automated single-wafer process development with up to three chambers

Key Benefits:

- Ideal for low-volume, R&D processing

- Economical entry to single-wafer processing

- Improved process quality and consistency

- Easy scale-up path to automated production

- Smallest Solstice system footprint

The Solstice® LT a full-featured, easy-to-use for electroplating and surface preparation application, can process a broad range of wafer sizes down to 75mm. In addition to electroplating, the system can perform high-pressure metal lift-off (MLO) spray acid applications such as UBM etch, and more. The LT accommodates up to three chambers for manual-load, semi-automated process development, or low-volume or R&D production. The systems use the same software and controls, and the same selection of chambers as the Solstice S4 and S8 configurations, providing an easy scale-up to automated production as capacity need expand.

The Solstice LT system chambers may be configured with a mix of different plating and surface prep chambers, including: GoldPro, CopperMax, Wet Etch, MLO, and Advanced Packaging.

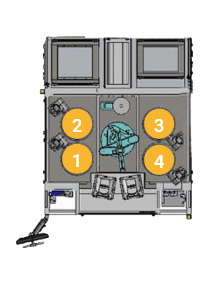

Solstice® S4

Advanced, single-wafer, high-throughput ECD and surface preparation, with up to four chambers

TOP VIEW

Up to 4 chambers, for fully automated, cassette, high-level production

Solstice® S4

Advanced, single-wafer, high-throughput ECD and surface preparation, with up to four chambers

Key Benefits:

- Ideal for mid-level volume processing

- Smaller footprint and lower cost than Solstice S8

- High plating rates, excellent throughput

- Exceptional quality plating and surface prep

- Special processing chambers can substantially reduce plating costs

- Superior process control and excellent uniformity

The Solstice® S4 automated electroplating systems are high-speed, fully -automated, 4-chamber tool designed for electroplating as well as surface preparation wet processing. The S4 provides all the essential features and capabilities of the S8, but with fewer chambers, a smaller footprint, and a lower price. The S4 can be ideal for users with simpler processing needs or who require an economical entry point into mid-level automated single-wafer electroplating production with enhanced process control.

The Solstice S4’s four chambers may be configured with a mix of different plating and surface prep chambers: GoldPro, CopperMax, Wet Etch, MLO, and Advanced Packaging.

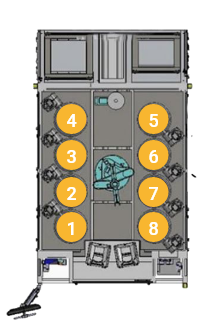

Solstice® S8

Advanced single-wafer electroplating and surface preparation, with up to eight chambers

TOP VIEW

Up to 8 chambers, for fully automated, cassette/to/cassette, high/level production

Solstice® S8

Advanced single-wafer electroplating and surface preparation, with up to eight chambers

Key Benefits:

- Ideal for high- volume processing

- High plating rates, excellent throughput

- Exceptional quality plating and surface prep

- Special processing chambers can substantially reduce plating costs

- Superior process control and excellent uniformity

The Solstice® S8 is the most powerful, easy-to-use, and cost-efficient route to single-wafer volume production for many applications. The fully automated chamber tool is designed for advanced wafer surface preparation and electroplating.

The S8 is engineered to deliver class-leading performance and exceptional operational flexibility. Its unique platform enables it to handle a spectrum of wet processes, from electroplating to high-pressure metal lift-off (MLO) to UBM etch and much more. The system is designed to accommodate many different substrate types, both transparent and opaque, from ultra thin to bonded. With its ability to deliver high-quality plating of a wide range of metals, the Solstice S8 can significantly reduce plating costs.

Solstice gives wet bench users an attractive, affordable, and easy upgrade path to the benefits of high-speed, cassette-to-cassette automated processing. The eight chambers of this system may be configured with a mix of different plating and surface prep chambers: GoldPro, CopperMax, Wet Etch, MLO, and Advanced Packaging.