Solstice® GoldPro™ Gold Electroplating

No compromise. Plating rate and uniformity performance results.

Leading manufacturers of GaAs and GaN devices are choosing Solstice GoldPro as their plating technology for applications from RF to VCSELs and microLEDs.

Our Solstice® GoldPro™ electrochemical deposition plating systems are designed to deliver efficiency, speed, and improved cost of ownership to your process. The system leverages our proprietary fluid flow and electric field shaping technology to give you high plating rates and uniform depositions every time.

In addition, plating reactors can be supplied with chemistry via individual tanks or shared tanks. Nitrogen protection is offered in the bath and in the plating reactor to maximize sulfite bath life. Our GoldPro technology is further differentiated by its ability to plate highly uniform features without the added maintenance complexity of submerged agitators.

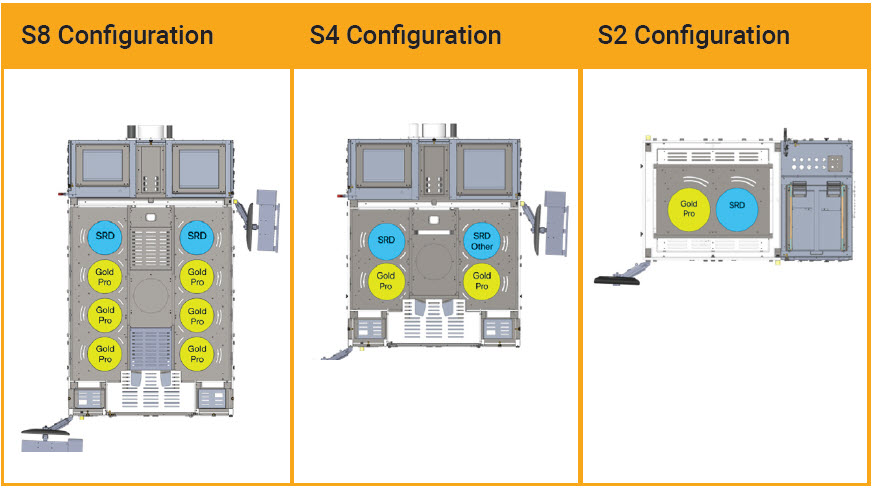

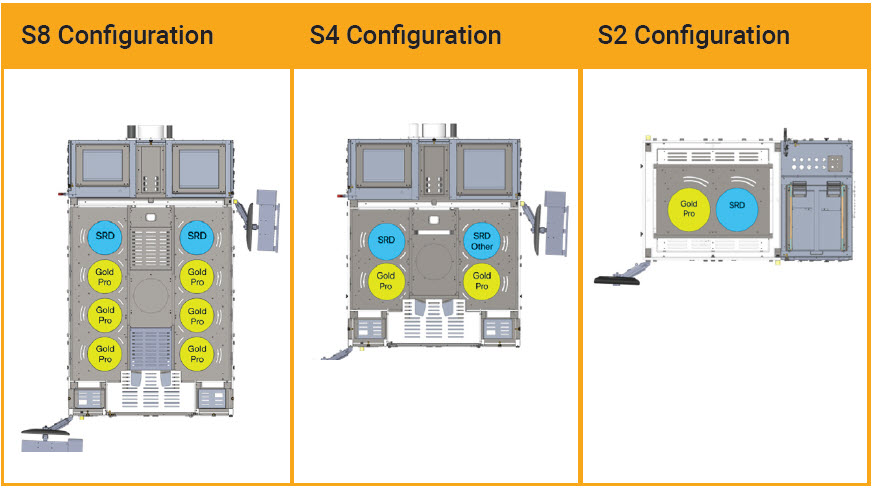

Solstice configurations with multiple chambers can be paired with one or more SRD chambers.

Key Applications

Key Markets

- Automotive

- Internet of things (IoT)

- Power

- 5G Communications

Features

- Advanced fluidics and electric field control

- Nitrogen bath life protection

- Closed loop bath control

- Automated and programmable dosing

Performance |

GoldPro |

| Within Feature Uniformity | <1.5% |

| Within Die Uniformity | <1% |

| Within-Wafer Uniformity | <3% |

| Wafer-to-Wafer Uniformity | <4% |

| Step Coverage | >90% |

| Feature Size | <1 micron wide |

| Plating Overburden | <1 micron |

Leading manufacturers of GaAs and GaN devices are choosing Solstice GoldPro as their plating technology for applications from RF to VCSELs and microLEDs.

Our Solstice® GoldPro™ electrochemical deposition plating systems are designed to deliver efficiency, speed, and improved cost of ownership to your process. The system leverages our proprietary fluid flow and electric field shaping technology to give you high plating rates and uniform depositions every time.

In addition, plating reactors can be supplied with chemistry via individual tanks or shared tanks. Nitrogen protection is offered in the bath and in the plating reactor to maximize sulfite bath life. Our GoldPro technology is further differentiated by its ability to plate highly uniform features without the added maintenance complexity of submerged agitators.

Solstice configurations with multiple chambers can be paired with one or more SRD chambers.