Solstice® Advanced Packaging System

Highly Flexible with Wide Range of Capabilities

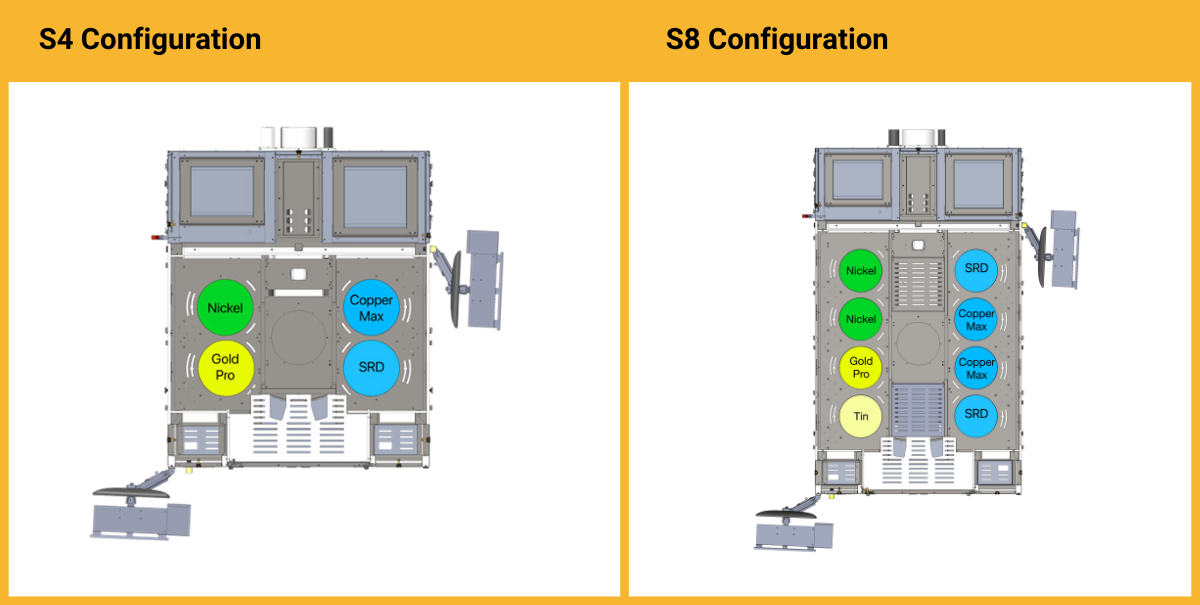

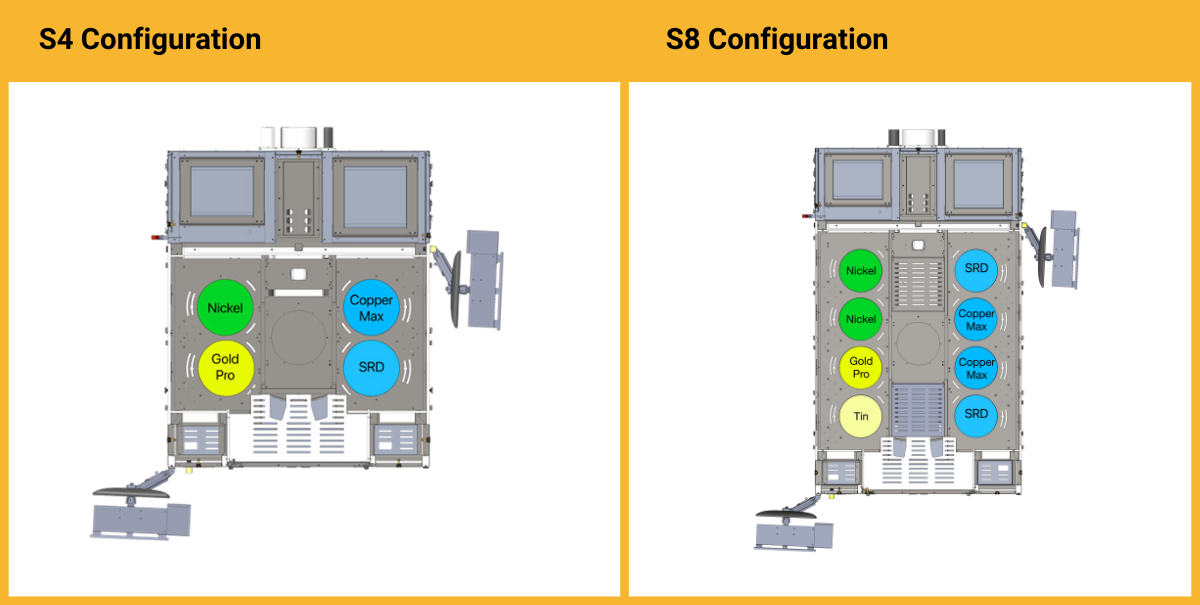

Our Solstice® advanced packaging system combines multiple process technologies to address advanced packaging applications. This system is configured for multi-metal stacks, including common copper-nickel-gold stacks, tin-silver alloys, and more. Armed with our class leading GoldPro™, CopperMax™, and Gen4 ECD Reactors, our Solstice platform can process wafers in sequential operations with minimal queue time between layers, preventing oxidation or layer adhesion problems.

Further, our proven Solstice advanced packaging processing technology performs fine uniformity within wafer and within feature—both critical capabilities for high-quality bonding and final packaging. You can rely on this system for bumping and metallization of a wide range of devices.

Our Solstice® advanced packaging system combines multiple process technologies to address advanced packaging applications. This system is configured for multi-metal stacks, including common copper-nickel-gold stacks, tin-silver alloys, and more. Armed with our class leading GoldPro™, CopperMax™, and Gen4 ECD Reactors, our Solstice platform can process wafers in sequential operations with minimal queue time between layers, preventing oxidation or layer adhesion problems.

Further, our proven Solstice advanced packaging processing technology performs fine uniformity within wafer and within feature—both critical capabilities for high-quality bonding and final packaging. You can rely on this system for bumping and metallization of a wide range of devices.