Trident SST

Advanced Spray Solvent Tools

For semiconductor batch processing

Next-generation SST

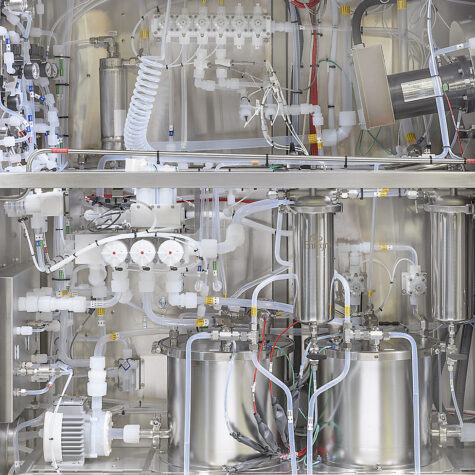

The Trident™ Spray Solvent Tools (SST) from ClassOne Technology are the next generation of batch-processing systems for metal lift-off, photoresist strip, polymer removal, and other solvent-based processes.

For substrates up to 200mm

Trident Spray Solvent Tool models are available for up to 200mm substrates — with two, four, or six heated chemical tanks; and a wide range of rotors. ClassOne can accommodate a range of wafer sizes, engineering rotors for most shapes and sizes. These systems include ClassOne’s proven Windows®10-based Solaris™ controller and provide remote login, data logging, GEM/SECSII communications, and reliability reporting.

These spray solvent tools utilize precision spray nozzles to deliver a continuous, uniform shower of solvent or rinse water, which enhances process performance.

Trident SSTs increase productivity and uptime while significantly reducing cost of ownership — with system pricing that is significantly lower than competitive spray solvent tools.

See also:

Key Features

- 2-, 4-, or 6-tank models

- Wide range of rotors

- Windows®10-based Solaris controller

- Remote login, data logging, and GEM/SECSII

Major Benefits

- Significantly lower CoO

- Reduced chemical consumption

- Reduced defects

- Shorter process time

- Easier operation and control

Next-generation SST

The Trident™ Spray Solvent Tools (SST) from ClassOne Technology are the next generation of batch-processing systems for metal lift-off, photoresist strip, polymer removal, and other solvent-based processes.

For substrates up to 200mm

Trident Spray Solvent Tool models are available for up to 200mm substrates — with two, four, or six heated chemical tanks; and a wide range of rotors. ClassOne can accommodate a range of wafer sizes, engineering rotors for most shapes and sizes. These systems include ClassOne’s proven Windows®10-based Solaris™ controller and provide remote login, data logging, GEM/SECSII communications, and reliability reporting.

These spray solvent tools utilize precision spray nozzles to deliver a continuous, uniform shower of solvent or rinse water, which enhances process performance.

Trident SSTs increase productivity and uptime while significantly reducing cost of ownership — with system pricing that is significantly lower than competitive spray solvent tools.