Solstice LT

Electroplating Development Systems

Semi-automated single-wafer Process

Development – with up to three chambers

Smarter, easier plating process development

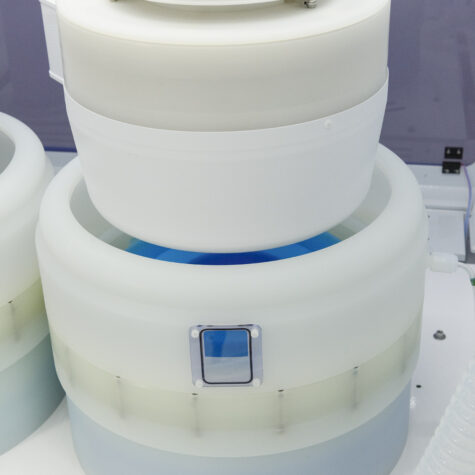

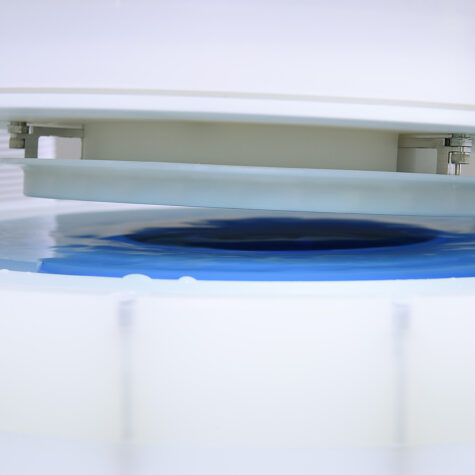

The Solstice® LT is a full-featured, easy-to-use process development and semiconductor plating equipment for electrochemical deposition (ECD) and surface preparation applications on 200mm and smaller substrates. The LT is engineered to deliver class-leading performance and exceptional operational flexibility. The unique Solstice platform enables it to handle a broad spectrum of processes, from electroplating to high-pressure metal lift-off to spray acid applications such as UBM etch, and more.

The Solstice LT accommodates up to three chambers for manual-load, semi-automated process development, or low-volume production. It may be configured with two ECD chambers – or one ECD and one prewet chamber – or two ECD plus one vacuum prewet chamber on the side, which is the Solstice LT3. All LT systems feature automated recipe execution and use the same software and controls and the same selection of chambers as the Solstice S4 and S8. This provides a natural, easy route for scaling up to automated production as the user expands capacity. No retraining is needed.

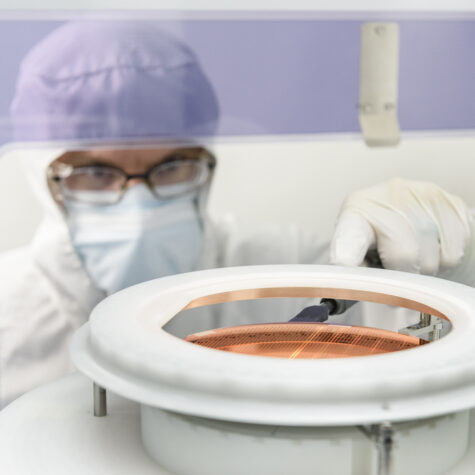

The Solstice LT features manual wafer loading and automated wafer processing.

Streamlining your path to automated plating

The Solstice LT gives wet bench users an attractive and affordable entry point to the benefits of advanced, automated plating and surface preparation, with major improvements in consistency, throughput, and safety – all with state-of-the-art features and control in a very compact footprint.

See also:

KEY FEATURES

- For 75mm to 200mm wafer processing

- Up to 3 chambers

- 2 ECD or 2 ECD plus 1 vacuum prewet chamber

- Manual wafer load/unload

- Automated recipe execution

- Software and chambers same as S4 and S8 systems

MAJOR BENEFITS

- Economical entry to single-wafer processing

- Improved process quality and consistency

- Easy scale-up path to automated production

- Smallest Solstice system footprint

Smarter, easier plating process development

The Solstice® LT is a full-featured, easy-to-use process development and semiconductor plating equipment for electrochemical deposition (ECD) and surface preparation applications on 200mm and smaller substrates. The LT is engineered to deliver class-leading performance and exceptional operational flexibility. The unique Solstice platform enables it to handle a broad spectrum of processes, from electroplating to high-pressure metal lift-off to spray acid applications such as UBM etch, and more.

The Solstice LT accommodates up to three chambers for manual-load, semi-automated process development, or low-volume production. It may be configured with two ECD chambers – or one ECD and one prewet chamber – or two ECD plus one vacuum prewet chamber on the side, which is the Solstice LT3. All LT systems feature automated recipe execution and use the same software and controls and the same selection of chambers as the Solstice S4 and S8. This provides a natural, easy route for scaling up to automated production as the user expands capacity. No retraining is needed.

The Solstice LT features manual wafer loading and automated wafer processing.

Streamlining your path to automated plating

The Solstice LT gives wet bench users an attractive and affordable entry point to the benefits of advanced, automated plating and surface preparation, with major improvements in consistency, throughput, and safety – all with state-of-the-art features and control in a very compact footprint.