Solstice® CopperMax™ Copper Electroplating

High Performance with Low Cost of Ownership

Leading manufacturers are choosing Solstice CopperMax as their plating technology for through-silicon via (TSV), through-glass via (TGV), damascene and copper pillar features.

Our Solstice® CopperMax™ system is designed to deliver high-performance copper plating at a low cost of ownership. Capable of plating a wide variety of feature types, the CopperMax chamber uses a cationic exchange membrane to protect additives from premature degradation at the anode. This results in 90%+ savings in bath additive costs.

In addition, CopperMax uses our proprietary fluid flow and electric field shaping technology to achieve high plating rates and uniform deposition. With the ability to deposit film with optimal grain orientation, our Solstice platform has been selected for emerging applications such as hybrid bonding and advanced packaging. Improve the performance of your copper process with Solstice CopperMax.

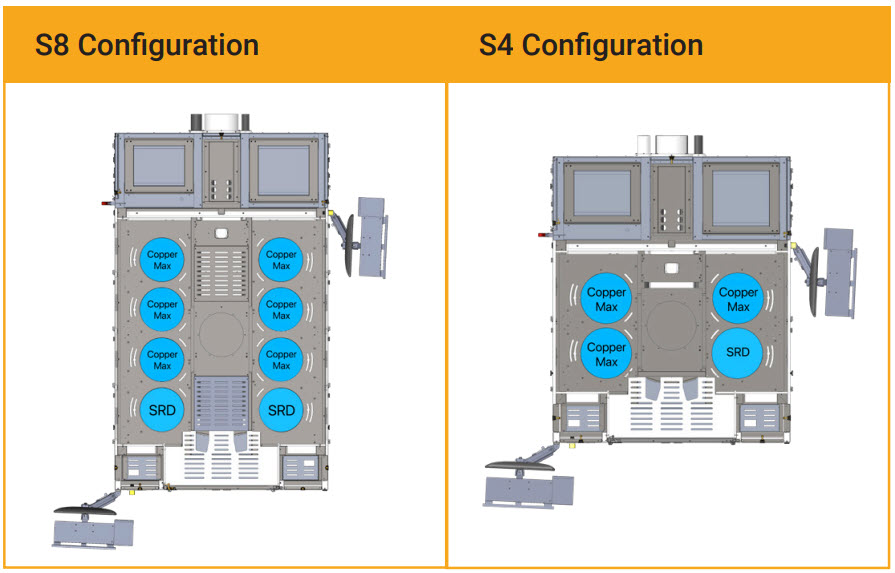

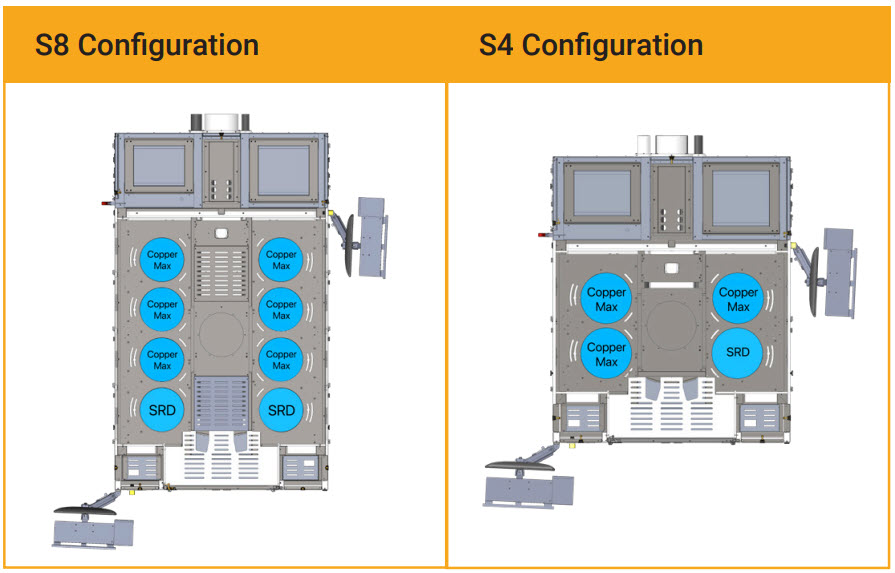

Solstice configurations with multiple chambers can be paired with one or more SRD chambers.

Key Applications

- Copper Pillar Plating

- Copper TSV Fill Plating

- Copper RDL Plating

- Copper Damascene Fill

- Solder Bump Plating

Key Markets

- Automotive

- Internet of things (IoT)

- Power

- 5G Communications

- MicroLED

Features

- Cationic exchange membrane

- Separates bath and additives from anode

- Greatly reduced cost of additives

| Process | Conventional Chamber | CopperMAX | Savings |

| TSV Bath | 0.80 ml/A-Hr | 0.020 ml/A-Hr | 97.5% |

| Damascene Bath | 0.52 ml/A-Hr | 0.008 ml/A-Hr | 98.4% |

| High Rate Bath | 0.67 ml/A-Hr | 0.028 ml/A-Hr | 95.8% |

Additive consumption reduction resulting in up to a $300,000 reduction in annual cost of ownership.

Leading manufacturers are choosing Solstice CopperMax as their plating technology for through-silicon via (TSV), through-glass via (TGV), damascene and copper pillar features.

Our Solstice® CopperMax™ system is designed to deliver high-performance copper plating at a low cost of ownership. Capable of plating a wide variety of feature types, the CopperMax chamber uses a cationic exchange membrane to protect additives from premature degradation at the anode. This results in 90%+ savings in bath additive costs.

In addition, CopperMax uses our proprietary fluid flow and electric field shaping technology to achieve high plating rates and uniform deposition. With the ability to deposit film with optimal grain orientation, our Solstice platform has been selected for emerging applications such as hybrid bonding and advanced packaging. Improve the performance of your copper process with Solstice CopperMax.

Solstice configurations with multiple chambers can be paired with one or more SRD chambers.