UBM and Patterned Metal Wet Etch

Using Solstice® Wet Etch System

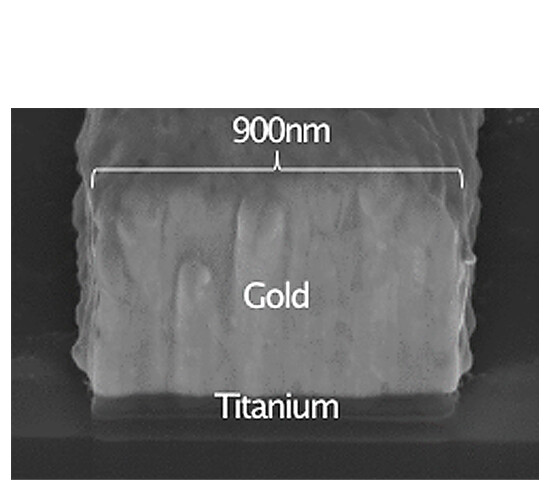

Patterned metal etching is used for under-bump metallization (UBM) in wafer-level packaging applications, as well as feature isolation following plating and photoresist strip processing. Key considerations for UBM and metal wet etch are cross-wafer uniformity, repeatability, undercut or critical dimension (CD) loss, cost-of-ownership and throughput.

The Solstice platform offers world-class cross-wafer uniformity due to its flood flow spray and precision rpm control. End-point detection is standard for patterned metal etch applications to ensure minimal possible undercut and CD loss. Our wet etch processing technology delivers industry-leading plating rates and uniformity to ensure optimal precision, control and performance.

Applications

- Wafer-level packaging

- Flip chip

Features

- High flexibility

- Cross-wafer uniformity

- Run-to-run repeatability

Benefits

- Low cost of ownership

- High flexibility

- Process effectiveness

Patterned metal etching is used for under-bump metallization (UBM) in wafer-level packaging applications, as well as feature isolation following plating and photoresist strip processing. Key considerations for UBM and metal wet etch are cross-wafer uniformity, repeatability, undercut or critical dimension (CD) loss, cost-of-ownership and throughput.

The Solstice platform offers world-class cross-wafer uniformity due to its flood flow spray and precision rpm control. End-point detection is standard for patterned metal etch applications to ensure minimal possible undercut and CD loss. Our wet etch processing technology delivers industry-leading plating rates and uniformity to ensure optimal precision, control and performance.

Applications

- Wafer-level packaging

- Flip chip

Features

- High flexibility

- Cross-wafer uniformity

- Run-to-run repeatability

Benefits

- Low cost of ownership

- High flexibility

- Process effectiveness