Copper Damascene Fill Plating

Using the Solstice® CopperMax™ Reactor

Copper (Dual) Damascene process is important for many applications because it allows for high density interconnect between layers on ICs. The damascene process is started with patterned trenches and vias that are etched into the substrate. Once these etched features are covered with a conformal seed in a PVD process, the wafer is ready for plating. Plating challenges start with the thin seed covering the damascene features. Solstice allows for controlled entry to the bath and precise electrical wave forms to protect the Copper seed layer and allow uniform plating to start. Once in the plating reactor, the plating on the wafer surface is controlled by expensive, highly engineered organic additives that enable seam-free, bottom-up fill.

These additives, however, are readily destroyed when they come in contact with the copper anode of the plating system. This necessitates ongoing replenishment of additives and significantly increases process costs. Our proprietary Solstice® CopperMax™ reactor integrates a cationic exchange membrane that separates organic additives from the anode while still allowing high-speed copper cation movement to the wafer. This enables higher plating rates while routinely reducing user chemistry costs by more than 95% – and also delivering excellently plated feature uniformity.

Eliminating Additive Breakdown

The proprietary design of the Solstice CopperMax reactor dramatically reduces the deterioration of organic additives by using a cationic exchange membrane to keep additives from contacting the anode. This significantly reduces chemistry costs while enhancing copper plating quality.

In other reactors, the plating behavior shifts rapidly as additives break down. The bath metrology begins to return inaccurate readings, which leads to erroneous dosing.

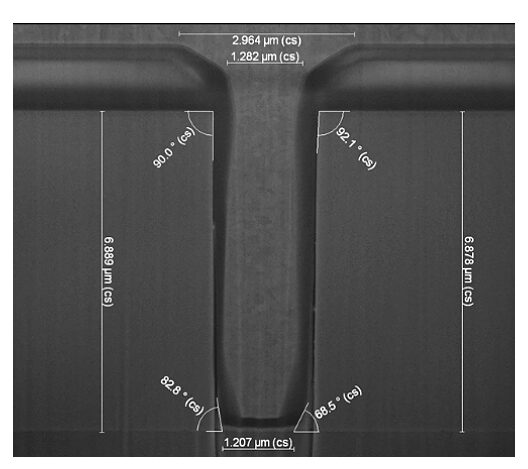

High-aspect-ratio plated damascene trench.

Technical Data

| Wafer Sizes | 75-200mm (configurable to non-standard sizes, e.g., 160mm) |

| Wafer Thickness | 150μm to >6mm |

| Wafer Materials | Silicon, GaAs, GaN on Si, GaN on Sapphire, Sapphire, Transparent Substrates, and more |

| Flow Rate | 25 lpm |

| Process Time | <3 minutes/wafer, <20 min for 5×50μm (dependent on feature) |

| Within-Wafer Uniformity | <5% 3-sigma |

| Wafer-to-Wafer Uniformity | <1% (mean-to-mean) |

| Fill Quality | Void-free |

| Bath Life | 50 amp-hours per liter (with proper chemistry management) |

Applications

- Interconnect

- CMOS backplane wafer

- Hybrid bonding

- And more…

Features

- Cation exchange membrane to reduce additive use

- Continuously filtered chemistry, optional carbon filtration

- High-precision wafer rotation

- Adjustable diffuser

- Dry-contact, low-maintenance plating rotor

- Customized seal reach

- Levitronix pump with LeviFlow

Benefits

- Additive costs reduced >95%

- Maximized bath life

- Extremely uniform field profile

- Seal reach aligns to existing integration

- Continuously cleaner chemistry

- Precise, consistent flow rate control

The single-wafer processing Solstice Platform is available with 8, 4, 3 or 2 chambers in customizable configurations, depending on the applications you require.