High-Step-Coverage, High-Rate Gold TWV Plating

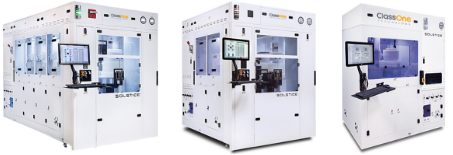

Using the Solstice® GoldPro™ Reactor

High-speed plating in a gold sulfite bath is sensitive to localized flow vectors due to the relatively slow diffusion rate of gold complex ions. As a result, you may find that sub-optimal electrolyte flow profile can lead to non-uniform deposition rates across the wafer. In immersion platers, and most fountain plater systems, a very low plating rate must be used to overcome this issue.

Our proprietary Solstice® GoldPro™ reactor design generates randomized fluid vectors at the diffusion layer of the wafer and uses the physics of a rotating disc electrode to provide you optimal conditions. This supports both high plating rates and high step coverage and ensures the diffusion layer is as thin as is practical. It also helps ensure that fluid motion remains directionless. The result is higher throughput without sacrificing coverage.

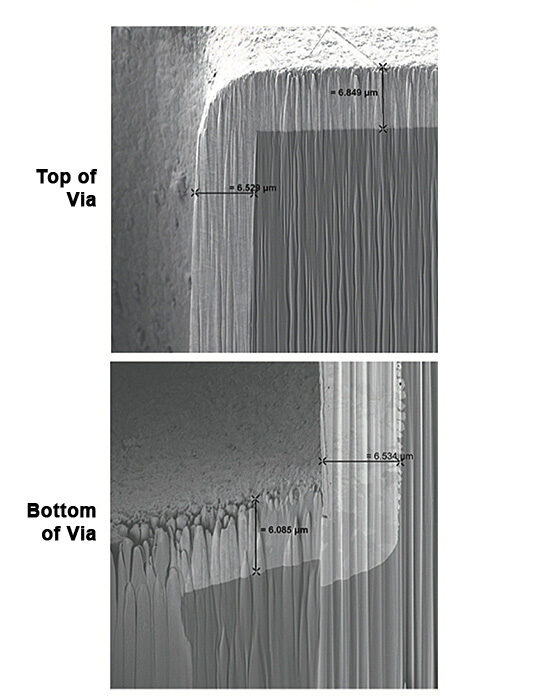

Example of a high-step coverage gold through-wafer via TWV plating.

The proprietary design of the Solstice GoldPro reactor is able to generate randomized fluid vectors at the diffusion layer of the wafer to optimize gold plating.

Applications

- Backside via liner

- TWV (through-wafer via) liner for electrical or thermal ground

- Backside contact

- Bond pad fill

- And more…

Features

- Randomized fluid vectoring

- Adjustable diffuser

- Dissolved oxygen control

- Dry-contact, low-maintenance plating rotor

- Customized seal reach

- Continuously filtered chemistry loop

- Optional carbon filtration

- Levitronix pump with LeviFlow

Benefits

- High plating rate and high uniformity

- Extremely uniform field profile

- Maximized bath life

- Seal reach aligns to existing integration

- Continuously cleaner chemistry

- Precise, consistent flow rate control

The single-wafer processing Solstice Platform is available with 8, 4, 3 or 2 chambers in customizable configurations, depending on the applications you require.

Technical Data

| Wafer Sizes | 75-200mm (configurable to non-standard sizes, e.g., 160mm) |

| Wafer Thickness | 150μm to >6mm |

| Wafer Materials | Silicon, GaAs, GaN on Si, GaN on Sapphire, Sapphire, Transparent Substrates, and more |

| Flow Rate | 10-60 lpm (dependent on wafer size) |

| Plating Rate | Up to 150μm/minute (dependent on chemistry) |

| Within-Wafer Uniformity | <3% (range 2*mean) |

| Wafer-to-Wafer Uniformity | 1% (mean-to-mean) |

| Step Coverage | 70-93% (dependent on aspect ratio) |

| Roughness | <2kÅ |

High-speed plating in a gold sulfite bath is sensitive to localized flow vectors due to the relatively slow diffusion rate of gold complex ions. As a result, you may find that sub-optimal electrolyte flow profile can lead to non-uniform deposition rates across the wafer. In immersion platers, and most fountain plater systems, a very low plating rate must be used to overcome this issue.

Our proprietary Solstice® GoldPro™ reactor design generates randomized fluid vectors at the diffusion layer of the wafer and uses the physics of a rotating disc electrode to provide you optimal conditions. This supports both high plating rates and high step coverage and ensures the diffusion layer is as thin as is practical. It also helps ensure that fluid motion remains directionless. The result is higher throughput without sacrificing coverage.

Example of a high-step coverage gold through-wafer via TWV plating.

The proprietary design of the Solstice GoldPro reactor is able to generate randomized fluid vectors at the diffusion layer of the wafer to optimize gold plating.

Applications

- Backside via liner

- TWV (through-wafer via) liner for electrical or thermal ground

- Backside contact

- Bond pad fill

- And more…

Features

- Randomized fluid vectoring

- Adjustable diffuser

- Dissolved oxygen control

- Dry-contact, low-maintenance plating rotor

- Customized seal reach

- Continuously filtered chemistry loop

- Optional carbon filtration

- Levitronix pump with LeviFlow

Benefits

- High plating rate and high uniformity

- Extremely uniform field profile

- Maximized bath life

- Seal reach aligns to existing integration

- Continuously cleaner chemistry

- Precise, consistent flow rate control

The single-wafer processing Solstice Platform is available with 8, 4, 3 or 2 chambers in customizable configurations, depending on the applications you require.