Surface Preparation

Advanced Wet-processing Solutions for Ultimate Wafer Uniformity and Process Control

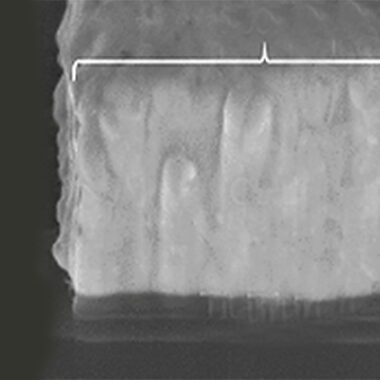

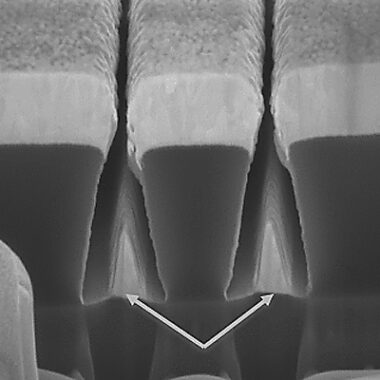

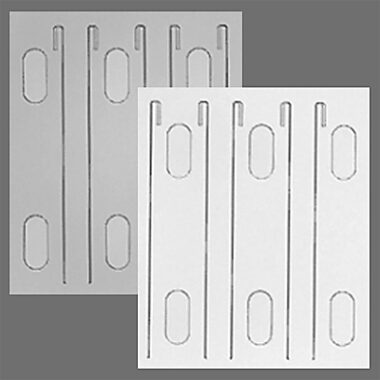

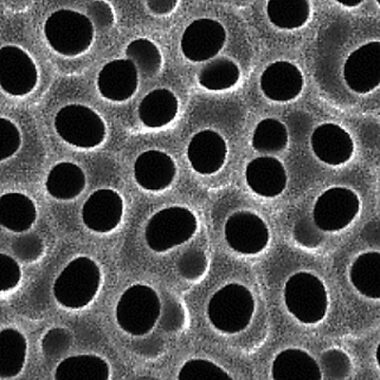

Our flagship Solstice® automated single-wafer platform offers a suite of surface preparation technologies, and features a face-down wafer processing scheme. This architecture allows for direct chemistry impingement on the wafer surface, enabling high speed and uniformity of etch, strip, and MLO processes. It also gives Solstice a huge safety advantage compared to common face-up architectures, as the fully sealed chambers efficiently drain and exhaust dangerous chemistry. The platform also easily integrates technology for temperature and concentration bath control, allowing for consistent wafer processing and extended bath life.

Additionally, the optional white light End Point Detection (EPD) feature provides efficient processing for film-removal etch, such as under-bump metallization (UBM) etch or seed etch. The FaceUp spin rinse dry (SRD) module mounts above the process chambers and provides fast, clean dries because of its chemically segregated location at the top of the tool. When it comes to safety, performance, and reliability, Solstice brings a wide array of surface prep capabilities for ClassOne’s customers.