ClassOne Announces Major Gold Plating Savings with Solstice

ClassOne Technology, manufacturer of budget-friendly wet processing equipment, is reporting significant savings in the plating of gold in ≤200mm applications using its Solstice® systems. The savings come from elimination of gold waste, faster and simpler processing, and innovative Solstice-enabled techniques that can substantially reduce gold usage.

“Many users have been spending millions of dollars on gold each year,” said Byron Exarcos, President of ClassOne Group. “It’s a major issue, especially in emerging markets such as lasers, LEDs, RF and MEMS which often require gold layers as thick as 3 to 35 microns. “That’s why they’re becoming keenly interested in Solstice to cut their gold spending.”

“One fundamental advantage of Solstice electroplating is its elimination of gold waste,” explained Kevin Witt, President of ClassOne Technology. “Previously used CVD and PVD methods deposited gold not just on the wafer but also on the entire chamber interior. That ‘oversprayed’ gold was difficult to remove and inefficient to reclaim — which led to a considerable net loss of gold. By contrast, Solstice deposits only on the wafer, so there’s no gold waste, and no need for cleaning or gold reclamation efforts.”

Witt pointed out that Solstice economies also come from the tool’s higher gold deposition speed. Plating at 150 to 300nm/min, it is roughly ten times faster than CVD and PVD methods. In addition, Solstice starts processing immediately, not requiring an hour or more for pump-down as vacuum-based tools do. All of this translates to additional savings, from higher throughput and more cost-efficient production.

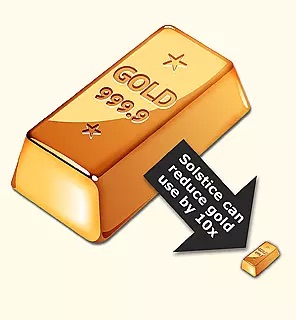

Innovative Solstice layering technique can cut gold usage dramatically

The unique 8-chamber design of the Solstice S8 enables it to readily replace a solid gold layer with a multi-metal stack — and reduce gold usage very substantially…

For example, a feature that previously required a 5µm layer of solid gold can now be replaced with a “sandwich” of 0.25µm Au, 1µm Ni, 2.5µm Cu, another 1µm Ni, topped with 0.25µm Au — to achieve equivalent functionality while reducing gold usage by a factor of ten! And Solstice’s multi-chamber design enables it to deposit all five layers in a single cycle; so no additional process steps or time are required to gain very significant cost savings.

ClassOne noted that over a year, total gold savings can grow quite large. For example, in the case cited above, if the solid gold 5µm layer covers 50% of a 150mm wafer area, and if the fab is running 1500 wafers per week through a metal lift-off process and gold costs $1200 per troy ounce — even if all oversprayed gold were recovered, the user’s annual gold expenditure would be roughly $2,150,000. However, if the special Solstice multi-metal layering technique were used, the total metal cost (for Au, Ni and Cu combined) would be reduced to approximately $108,000. This would yield an annual savings of over $2,042,000, which would more than pay back the cost of a Solstice. (Additional details on the Solstice multi-metal layering technique and gold-usage reduction may be seen on the ClassOne Technology website.)

The Solstice S8 provides eight modular chamber positions that can be used for plating a wide range of metals as well as performing additional processes. Solstice tools are available in three different models for production and development, and they serve many cost-sensitive emerging markets that use 200mm and smaller wafers. The systems are priced at less than half of what similarly configured plating systems from the larger manufacturers would cost — which is why Solstice has been described as “Advanced Plating for the Rest of Us.”

About ClassOne Technology

ClassOne Technology (classone.com) develops and delivers innovative wet-chemical equipment solutions especially for the budget-conscious users of smaller substrates, who traditionally have been underserved by larger equipment manufacturers. ClassOne’s products include electroplating, spin rinse drying, spray solvent tools and more. Based in Kalispell, Montana, ClassOne Technology is built upon many decades of experience from industry veterans who continue the ClassOne tradition of delivering first-class quality and performance at an affordable price. ClassOne Technology is a sister company to ClassOne Equipment (ClassOneEquipment.com), long respected as the industry’s premier provider of refurbished processing tools, with over 2,500 systems installed worldwide.