SOLSTICE

Solstice® Single-Wafer Processing Platform

Customizable, Modular, and Scalable Automated Single-Wafer Processing with Maximum ROI

Our flexible Solstice® single-wafer platform offers a broad portfolio of electroplating and surface preparation applications on a single, compact system. Engineered for reliability and uptime, Solstice delivers advanced performance with maximum throughput and wafer uniformity. Our team of process equipment experts integrated reliable, high-integrity, best-in-class components into an elegantly designed family of systems that are allow you to realize unparalleled cost efficiency and ROI.

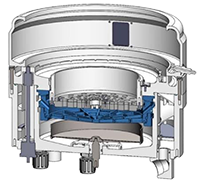

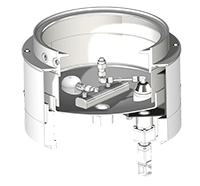

Available with up to 3, 4 or 8 chambers, The Solstice platform can accommodate a variety of substrate types, from traditional silicon devices to compound semiconductors and emerging materials like glass. The systems can reliably and expertly process wafers down to 75mm in diameter — whether mounted, thinned, flatted, bowed, or transparent — and can handle multiple wafer sizes on a single system. Wafer rotor changes take less than 5 minutes, minimizing system downtime and contributing to the platform’s ease of operation and maintenance.

Multiple Processes.

One Platform.

A key differentiator for Solstice is its flexibility and modular design. You can custom-configure the system you need by mixing and matching process technologies across both electroplating and surface prep, to create a turnkey solution that meets your specific process flow requirements. For example, if you need to perform both gold electroplating and metal liftoff on the same system, we can build a Solstice that meets this demand seamlessly. It’s as easy as that.

Purpose Built.

Volume Ready.

If you don’t require such diverse process capability but instead need specific processes ready for high-volume manufacturing, we offer dedicated, purpose-built configurations for both electroplating and surface prep applications. To learn more about these configurations, click on Explore by System.

ELECTROPLATING

SOLSTICE GOLDPRO

- World-class uniformity and speed for: fine feature gold fill, gold TWV, through mask gold plating

SOLSTICE COPPERMAX

- Cationic membrane-based copper plating for: Copper pillar, copper TSV and TWV, copper RDL, copper damascene

SOLSTICE PACKAGING

- Metal stacks for AP techniques: Nickel plating, copper pillar, solder bump, alloys and more

SURFACE PREPARATION

SOLSTICE WET ETCH

- High performance, better CoO, improved safety

- Face-down processing, end-point detection, face-up SRD

- Key processes: UBM etch, patterned metal etch, KOH etch, TSV cleans, RCA cleans

SOLSTICE MLO AND PHOTORESIST STRIP

- High-performance single-wafer automated solvent

- Effective strip and removal without wet transfers

- Key processes: MLO, photoresist strip, polymer removal

Contact us today to see how we can help you optimize your processes

and how our flexible and configurable Solstice platform can best serve your needs.

Explore By Model

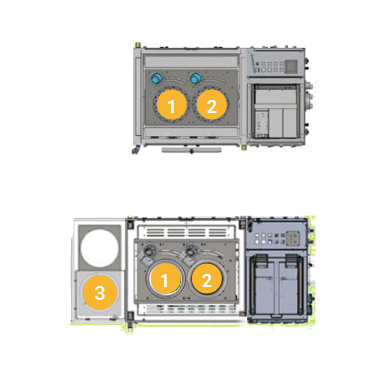

LT/LT3

- Up to 3 chambers: 2 ECD, or 2 ECD plus 1 vacuum prewet chamber

- Economical entry to single-wafer processing

- Easy scale-up path to automated production

- Improved process quality and consistency

- Smallest Solstice system footprint

S4

- Includes all the capabilities and performance benefits of S8, but with fewer chambers

- Smaller footprint and lower cost than S8

- Up to 75 wph throughput

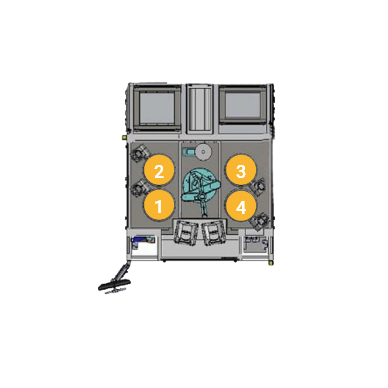

S8

- Eight chambers to enable many functions

- Configurable for exceptional plating and surface prep on a single tool, reducing footprint and saving costs

- Handles 75mm to 200mm substrates, including thin or bonded, and transparent or opaque

- High plating rates, excellent throughput, with superior process control and excellent uniformity