Solstice® Wet Etch System

Excellent Performance and Flexibility

Our wet etch configuration is designed to deliver you high performance, better cost of ownership, and improved safety. Our flexible fluidics design allows for multiple chemistries to be plumbed to each of the chambers. Inline heaters can be used for fine temperature control <±0.5°C for many applications. Recipe-addressable drain blocks and filtration can be configured for efficient reclaim and introduction of fresh chemistry. Additionally, optical endpoint detection can be used to dynamically adjust etch time and ensure precision film removal. The face-down orientation of our chambers seals the chemistry in the chamber and prevents operator exposure.

Our wet etch chambers can be combined with segregated face-up SRD chambers for cleans applications. The face-up SRD draws clean air directly from the HEPA filters, which aids in a speedy and clean dry that is segregated from the wet etch chambers. Enjoy great performance and safety with the Solstice® wet etch system.

Nom-uniformity of less than 5% in a copper film etch batch.

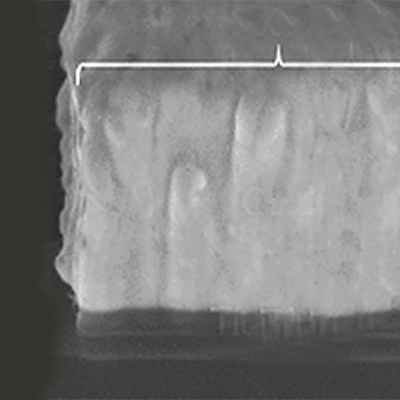

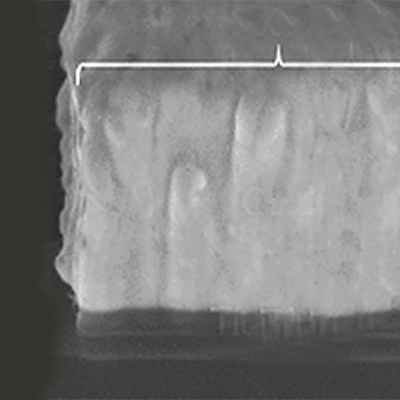

UBM etch with effectively zero undercut. Can be used with end point detection.

Solstice configurations with multiple chambers can be paired with one or more SRD chambers.

Capabilities

- UBM Etch

- Metal Etch

- Seed and Barrier Etch

- Oxide Etch

- Silicon Etch

- TSV Cleans

- RCA–SC1 Cleans

Our wet etch configuration is designed to deliver you high performance, better cost of ownership, and improved safety. Our flexible fluidics design allows for multiple chemistries to be plumbed to each of the chambers. Inline heaters can be used for fine temperature control <±0.5°C for many applications. Recipe-addressable drain blocks and filtration can be configured for efficient reclaim and introduction of fresh chemistry. Additionally, optical endpoint detection can be used to dynamically adjust etch time and ensure precision film removal. The face-down orientation of our chambers seals the chemistry in the chamber and prevents operator exposure.

Our wet etch chambers can be combined with segregated face-up SRD chambers for cleans applications. The face-up SRD draws clean air directly from the HEPA filters, which aids in a speedy and clean dry that is segregated from the wet etch chambers. Enjoy great performance and safety with the Solstice® wet etch system.

Nom-uniformity of less than 5% in a copper film etch batch.

UBM etch with effectively zero undercut. Can be used with end point detection.

Solstice configurations with multiple chambers can be paired with one or more SRD chambers.