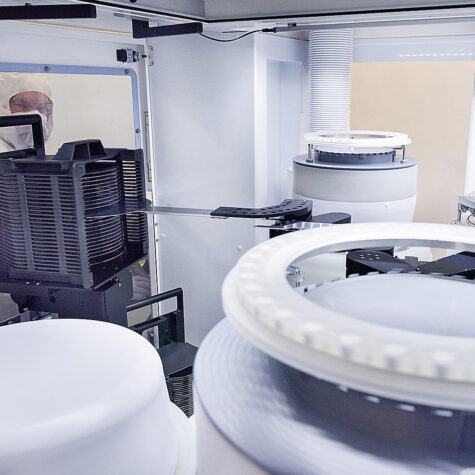

Solstice S4

Automated Electroplating Systems

Advanced, single-wafer, high-throughput ECD and Surface Preparation – with up to four chambers

Smaller yet very powerful

The Solstice® S4 automated electroplating systems are high-speed, fully-automated, 4-chambered tool designed for electrochemical deposition (ECD) as well as surface preparation wet processing – specifically for ≤200mm wafers. The S4 provides all the essential features and capabilities of the S8, but with fewer chambers, a smaller footprint, and a lower price. The S4 can be ideal for users with simpler processing needs or who require an economical entry point into mid-level automated single-wafer electroplating production with enhanced process control.

Four chambers for mid-level production

Permits up to 4 processing chambers

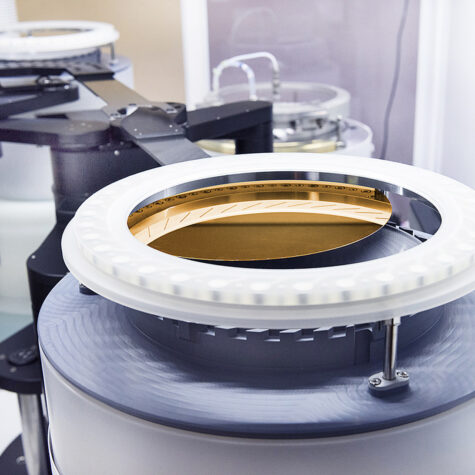

The S4 is engineered to deliver class-leading performance and exceptional operational flexibility. Its unique platform enables it to handle a broad spectrum of wet processes, from electroplating to high-pressure metal lift-off to UBM etch and much more. The system is designed to accommodate many different substrate types, both transparent and opaque, from very thin to bonded.

The Solstice S4 delivers high-quality plating of a wide range of metals, from gold and copper to nickel and indium. Specialized Solstice processes and chambers can significantly reduce plating costs, especially with gold, copper and other applications.

An easy entry point to full automation

Side view of the Solstice S4

The Solstice gives wet bench users an easy and affordable upgrade path to the benefits of high-speed cassette-to-cassette automated electroplating – along with major improvements in quality, consistency, throughput, safety, and control.

The four chambers of this system may be configured with a mix of different plating and surface prep chambers, specified at the time of purchase. All Solstice models share the same innovative high-performance chambers, software controls, and electronics. Each tool provides the same intuitive, touch-screen control, with GEM/SECSII interface, full reporting, and a great deal more.

See also:

KEY FEATURES

- Four chambers to enable multiple functions

- Cassette-to-cassette automation

- For 75mm to 200mm substrates

- Up to 75wph throughput

- Enables rapid diameter changes

- Automated recipe execution

- Handles thin or bonded, transparent or opaque substrates

- Wide range of processes for Au, Cu, Ni, In, Sn, Pt, alloys & more

- Au apps include VCSEL, TWV, Thin Layer Stacks, Au deplate & more

- Cu apps include TSV, Pillar, Bump, RDL, Damascene & more

MAJOR BENEFITS

- S8 capabilities, only fewer chambers

- Smaller footprint, lower cost than S8

- High plating rates, excellent throughput

- Exceptional quality plating and surface prep

- Special processing chambers can substantially reduce plating costs

- Superior process control and excellent uniformity

Smaller yet very powerful

The Solstice® S4 automated electroplating systems are high-speed, fully-automated, 4-chambered tool designed for electrochemical deposition (ECD) as well as surface preparation wet processing – specifically for ≤200mm wafers. The S4 provides all the essential features and capabilities of the S8, but with fewer chambers, a smaller footprint, and a lower price. The S4 can be ideal for users with simpler processing needs or who require an economical entry point into mid-level automated single-wafer electroplating production with enhanced process control.

Four chambers for mid-level production

Permits up to 4 processing chambers

The S4 is engineered to deliver class-leading performance and exceptional operational flexibility. Its unique platform enables it to handle a broad spectrum of wet processes, from electroplating to high-pressure metal lift-off to UBM etch and much more. The system is designed to accommodate many different substrate types, both transparent and opaque, from very thin to bonded.

The Solstice S4 delivers high-quality plating of a wide range of metals, from gold and copper to nickel and indium. Specialized Solstice processes and chambers can significantly reduce plating costs, especially with gold, copper and other applications.

An easy entry point to full automation

Side view of the Solstice S4

The Solstice gives wet bench users an easy and affordable upgrade path to the benefits of high-speed cassette-to-cassette automated electroplating – along with major improvements in quality, consistency, throughput, safety, and control.

The four chambers of this system may be configured with a mix of different plating and surface prep chambers, specified at the time of purchase. All Solstice models share the same innovative high-performance chambers, software controls, and electronics. Each tool provides the same intuitive, touch-screen control, with GEM/SECSII interface, full reporting, and a great deal more.